Division of Machine Design and Industrial System Engineering

06/09/2020 16:34

The Division of Machine Design - Industrial Systems Engineering of the Faculty of Transportation Mechanical Engineering in 2018. The Division is currently offering one degree programs in: Industrial Systems Engineering (ISE).

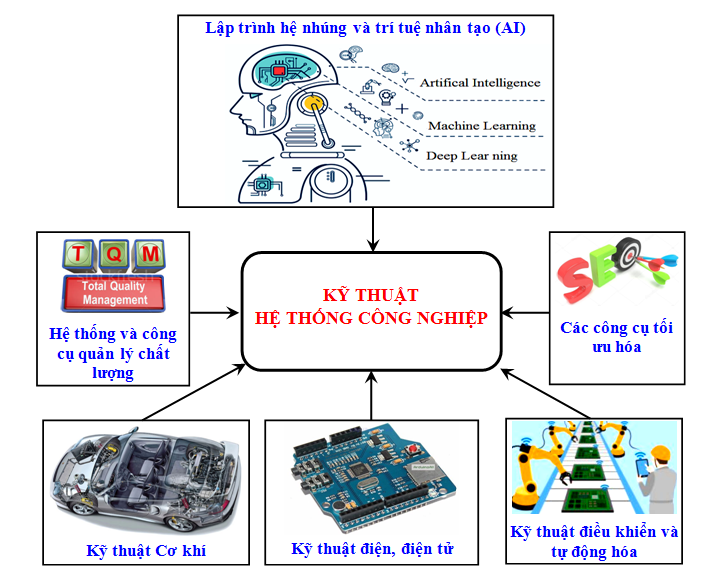

At present it offers undergraduate specialized of Industrial Systems Engineering which is a new major established in 2019, derived from the actual needs of the locality and the country. The objectives of the Industrial System Engineering is trains engineers with skills needed to solve production and service facility problems, to undertake the design, installation and management of integrated systems between people, materials, equipment, methods and energy, to improve productivity, ensure product and service quality at output, and reduce production and transportation costs hereby improving the competitiveness of businesses.

Mathematical modeling will apply mathematical model, computer, knowledge of economy, society, environment and human behavior to provide optimal solutions for production or service activities.

The program has 120 credits, including the body of knowledge:

+ Designing and development of industrial systems and products

+ Production management

+ Modeling and simulation

+ Scheduling and planning

+ Facility planning

+ Operations research

+ Quality management

+ Project management

+ Supply chain management

+ Multi-criteria decision making

The Division offers of many courses for other faculties of the University of Science and Techonology, the University of Danang. It has laboratories to carry out researches in some areas related to Mechanical and Production & Industrial Engineering. The Faculty actively participates in sponsored research and consultancy work.

LIST OF STAFFS IN DIVISION

|

No.

|

Photo

|

Full name, Diploma, Title

|

Contact information

|

Teaching courses

|

|

1

|

|

VŨ THỊ HẠNH

PhD., Lecturer

Head of Division

|

Tel: 0905.084.137

Email: vthanh@dut.udn.vn

|

Mechanical transmission

Base of machine design

Modeling and simulation

Technical economics

Quality control and management

|

|

2

|

|

LÊ CUNG

Assoc. Prof. Dr, Senior Lecturer

In charge of automatic production major (PFIEV)

Scientific CV

|

Tel: 0905.124.879

Email: lcung@dut.udn.vn

|

Mechanical transmission

Base of machine design

The principle of machine

Machine mechanics

Design factory

|

|

3

|

|

NGUYỄN VĂN YẾN

Assoc. Prof. Dr, Senior Lecturer

Scientific CV

|

Tel: 0914.038.888

Email: nvyen@ac.udn.vn

|

Mechanical transmission

Base machine design

Lifting equipment

Production technology

|

|

4

|

|

NGUYỄN CÔNG HÀNH

PhD., Lecturer

Scientific CV

|

Tel: 0989.294.901

Email: nchanh@dut.udn.vn

|

Moderation techniques

Modeling and simulation

CIM, FMS production system

|

|

5

|

|

THÁI BÁ CHIẾN

PhD., Lecturer

Scientific CV

|

Tel: 0986.616.682

Email: tbchien@dut.udn.vn

|

Technical drawing

Electrical Engineering

|

|

6

|

|

DƯƠNG THỌ

MSc., Senior Lecturer

Scientific CV

|

Tel: 0913.490.641

Email: dtho@dut.udn.vn

|

Graphics

Technical drawing

|

|

7

|

|

TÔN NỮ HUYỀN TRANG

MSc., Lecturer

|

Tel: 0918.35.7468

Email: htrangm@yahoo.com

|

Graphics

Technical drawing

Statistics in industry

Lean production system

Designing industrial products

|

|

8

|

|

HUỲNH ĐỨC TRÍ

MSc., Lecturer

Scientific CV

|

Tel: 0964.519.357

Email: hdtri@dut.udn.vn

|

Electrical Engineering

Apply IT in industry

Job design and labor measurement

Decision-making techniques

|

|

9

|

|

NGUYỄN NGỌC TÂN

PhD., Lecturer

|

Tel: 0938.707.290

Email: nntan@dut.udn.vn

|

Graphics

|

DEVELOPMENT DIRECTIONS

+ Completing and developing training program for Industrial Systems Engineering (ISE).

+ Training system integrating two systems: Bachelor (130 credits) and Engineer (180 credits).

+ Preparing to build and train a master's program in Industrial Systems Engineering (ISE).

- About Scientific research and technology transfer:

+ Design (production system design, service system design; mechanical engineering design).

+ Simulation of industrial systems in practice and in research.

+ Optimizing and improving real systems, applying results to the reality of production and services.

SCIENTIFIC RESEARCH AND TECHNOLOGY TRANSFER RESULTS

Scientific research topics: Lecturers in the Division of Machine Design - Industrial System Engineering, Faculty of Transportation Engineering have been participating in many scientific and technological topics at all levels, solving practical problems related to related to the industrial production sector, in the central provinces - Central Highlands and the whole country. The total number of topics at all levels has been carried out are 19 ministerial-level scientific research projects, UD-level scientific research projects and university-level scientific research projects. Most of the topics are highly applicable and accepted on schedule.

Scientific articles and reports: Lecturers of the Division of Machine Design - Industrial System Engineering have published 95 articles on the Proceedings of Conferences and Scientific Magazines (65 international articles, including 10 articles in SCI, SCIE and ISI journals).

Postgraduate guidance: Lecturers have been and are participating in guiding 34 graduate students and graduate students in related subjects.

Books and textbooks: In addition, in order to standardize lectures and serve in-depth training, lecturers have participated in compiling 9 textbooks and monographs in the field of teaching.

RESEARCH DIRECTIONS

- Design the operation model of a smart factory:

+ Design, simulate, and optimize the actual production line.

+ Simulate large and medium scale plant operations: logistics, production operations.

+ Simulate production areas: Robot work area, worker space.

.

- Provide solutions to meet lifecycle data management capabilities in the factory:

+ Research to provide suitable management and production solutions, when handling information changes during product development and improvement.

+ Synchronize between planning and production practice.

+ Deploy information related to the design, management, and manufacture of products to immediate development teams.

- Detect problems and offer solutions to help optimize production operations:

+ Research methods and apply production plan management tools to provide coping solutions in the production process to ensure synchronous and effective operation of the chain.

+ Simultaneously plan, manage constraints, make optimization plan in production process consistent with reality.

+ Predict potential risks to production processes and make recommendations in line with specific business management systems to prevent.

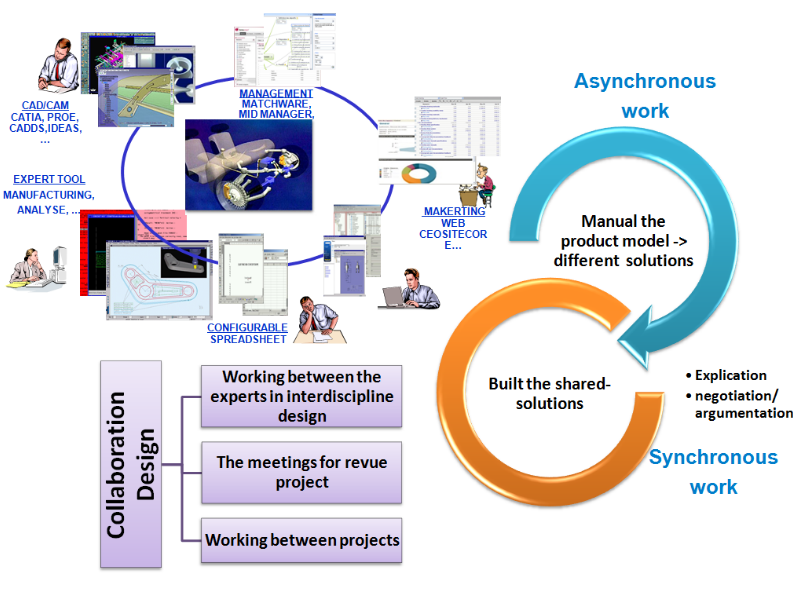

- Design working environment in the direction of integrated design, at the same time multi-disciplinary, multi-field:

+ Study remote, synchronous and independent working environments

+ Research work platforms suitable for multiple disciplines and disciplines

+ Design work platforms that pull close to the distance and minimize movements between participants